AUTOMATED CASING LASER WELDING TONG

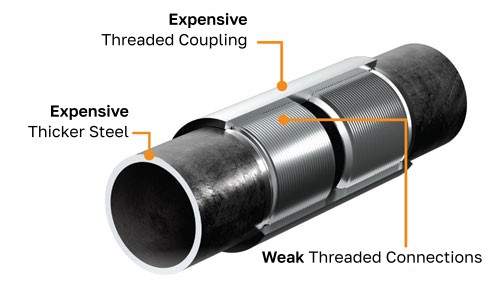

Increase the speed of drilling, improve casing quality and reduce the cost of oil well drilling by replacing weak expensive threaded & coupled connections with strong low cost welded joints

Overview

DRILL FASTER AT LOWER COST

ENABLES CASING WHILE DRILLING

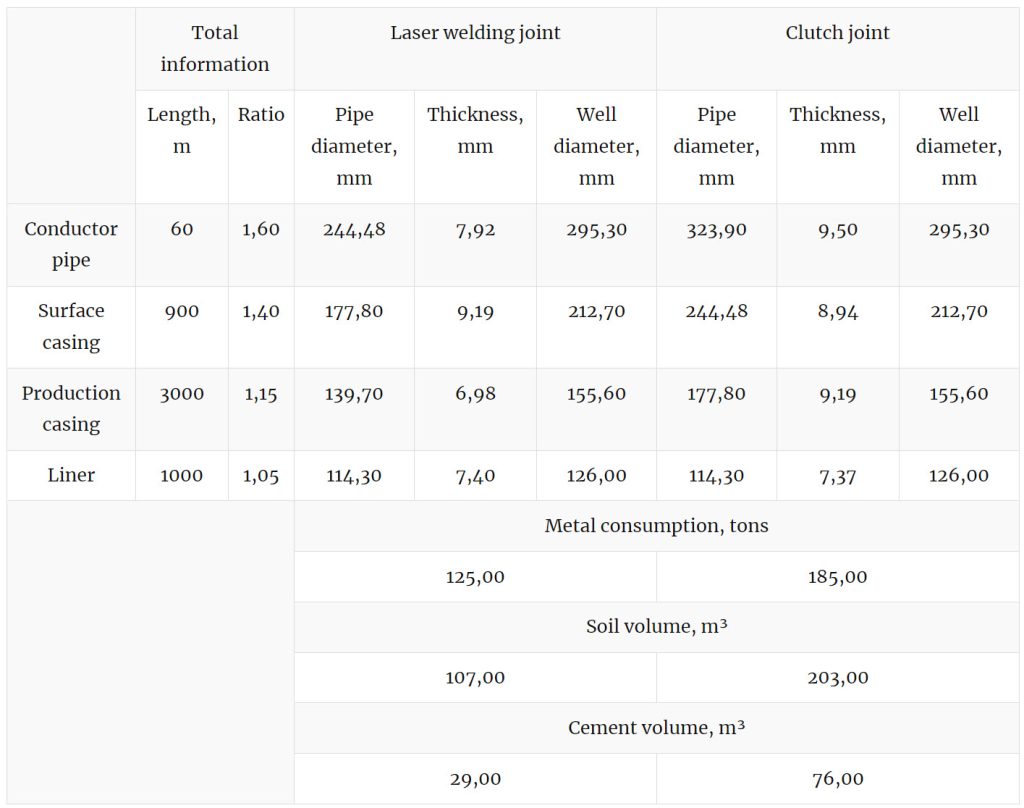

- GREATER THAN 30% reduction of metal consumption

- 2X reduction of removed soil rocks

- up to 3X reduction of cement

consumption

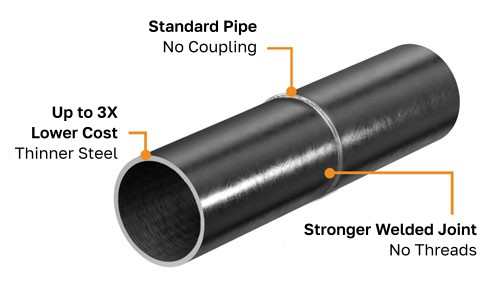

TongWELD REPLACES EXPENSIVE & EXPOSED THREADED & COUPLED CONNECTIONS

WITH LOWER COST & STRONGER WELDED JOINT

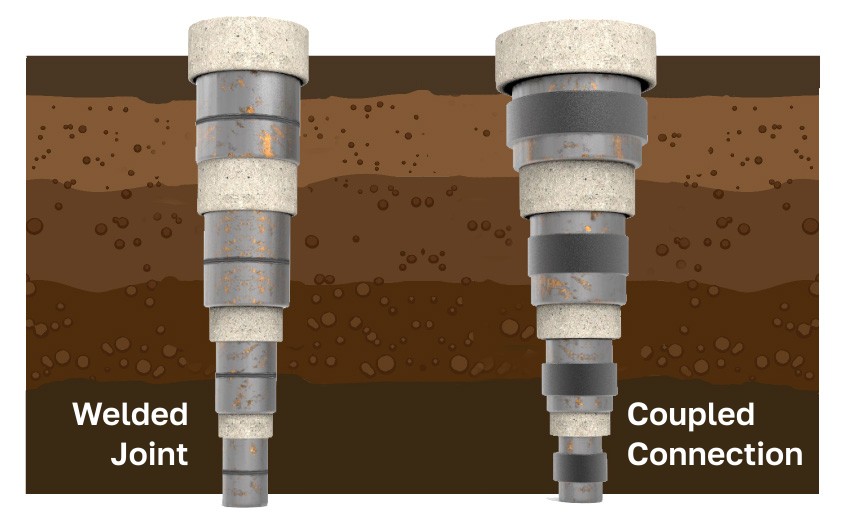

Threaded & coupled connections – disadvantages

- Most vulnerable parts of casing pipes, limiting their structural integrity.

- Weak and require the use of the more expensive grades of thicker steels, increasing the pipe weight and cost.

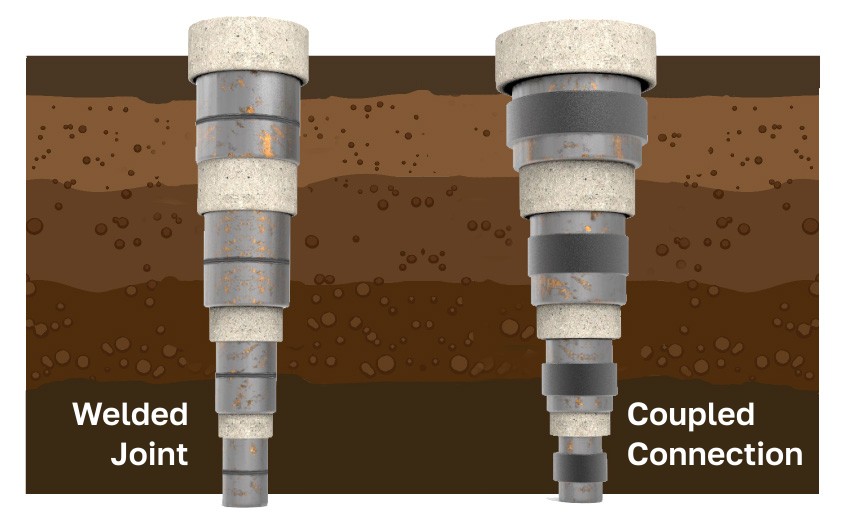

- Protrude and increase the diameter of the well, increasing the amount of removed soil rocks, and the volume of drilling fluid and cement.

- Create extra friction against well walls, resulting in complications in the casing advance.

- Have less available toque to overcome these complications through pipe rotation.

Automated Casing Drilling

LOWER DRILLING COST

- Utilize SMALLER DRILLING TOOL & WELL DIAMETER

- LESS VOLUME of Soil Rocks, Drilling Fluid & Cement

FASTER CASING ADVANCE

- FEWER COMPLICATIONS in Casing Advance Due to Absence of Protruding Coupled Parts

- MAXIMUM TORQUE AVAILABLE for Casing Rotation

HIGHER CASING QUALITY

- HIGH QUALITY Cementing with Casing Rotation

- HIGH STRENGTH & MORE HERMETIC Casing

Traditional Methods

HIGHER DRILLING COST

- Requires LARGER DRILLING TOOL & WELL DIAMETER

- LARGE VOLUME of Soil Rocks, Drilling Fluid & Cement

SLOWER CASING ADVANCE

- CASING ADVANCE COMPLICATIONS Due to Protruding Coupled Parts

- LESS TORQUE AVAILABLE for Casing Rotation

LOWER CASING QUALITY

- LOW QUALITY Cementing

- WEAKER STRENGTH & LESS HERMETIC Casing

TongWELD enables Drilling with Casing (DwC) Technology

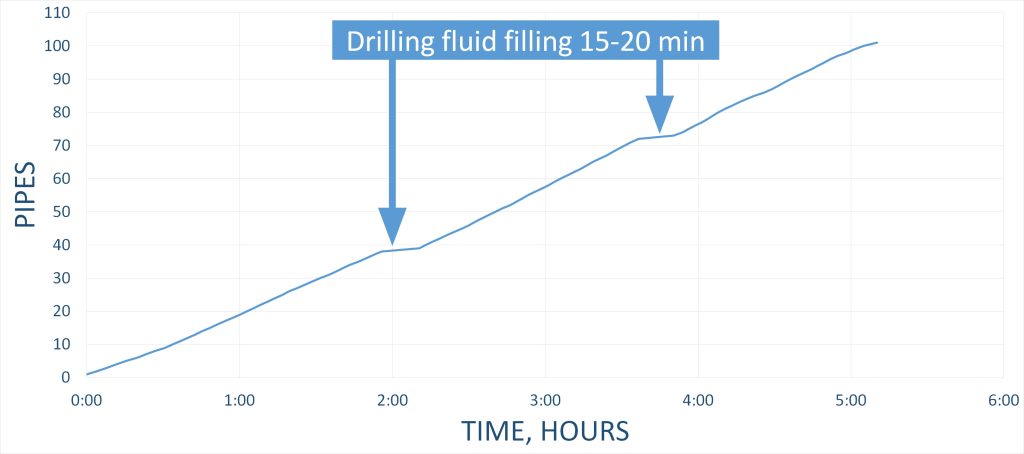

TongWELD helps overcome casing advance complications

- Replacing traditional coupled casing with laser welded joints reduces friction of casing against well walls and creates fewer complications in casing advance.

- When complications in casing advance still arise, they can be overcome by casing rotation. However, weak threaded & coupled connections significantly limit the maximum torque available for rotation.

- Because welded joints are several times stronger than threaded & coupled connections, the welded casing can be rotated with much higher torque. Unlike the coupled casing, welded casing can be rotated in both directions.

Enables Faster DwC Technology

- Wide adoption of Drilling with Casing technology has been hindered by high cost of threaded pipes and weak coupled connections.

- Stronger welded connections enable wide adoption of Drilling with Casing.

field operation

casing string parameters

| Total information | Laser welding joint | Coupled connection | ||||||

| Length, m | Ratio | Casing OD, inches | Thickness, mm | Wellbore ID, inches | Casing OD, inches | Thickness, mm | Wellbore ID, inches | |

| Conductor pipe | 60 | 1,60 | 9 5/8" | 7,92 | 11 5/8" | 12 3/4" | 9,50 | 15 1/2" |

| Surface casing | 900 | 1,40 | 7" | 9,19 | 8 3/8" | 9 5/8" | 8,94 | 11 9/16" |

| Production casing | 3000 | 1,15 | 5 1/2" | 6,98 | 6 1/8" | 7" | 9,19 | 8 11/16" |

| Liner | 1000 | 1,05 | 4 1/2" | 7,40 | 5" | 4 1/2" | 7,37 | 6" |

| Metal consumption, tons | ||||||||

| 125,00 | 185,00 | |||||||

| Soil volume, m³ | ||||||||

| 107,00 | 203,00 | |||||||

| Cement volume, m³ | ||||||||

| 29,00 | 76,00 | |||||||

weld properties

WELDED JOINTS ARE STRONGER and LOWER DRILLING COSTS

| 114 x 7.3 mm Pipe | Threaded Tapered Coupling | Welded Joint |

| Steel Type | Premium High Cost N80 Steel | LOW COST A 516-55 Steel |

| Yield Strength, kN | 1367 | >1600 |

| Maximum Pressure, bar | 623 | 700 |

| Maximum Torque, kNm | 13 | >34 |

| Drilling Tool Diameter, mm | 152 | 126 |

| Pipe Cost, $/km | 36000 | 20000 |

Welded Joint Testing

Torque Test

102 x 6.5 mm Pipe

23.4 kNm Force

NO WELD DAMAGE

Bending Stress Test

NO CRACKS

IN

WELD JOINT

Tensile Stress Test

NO

WELD

DAMAGE

specifications

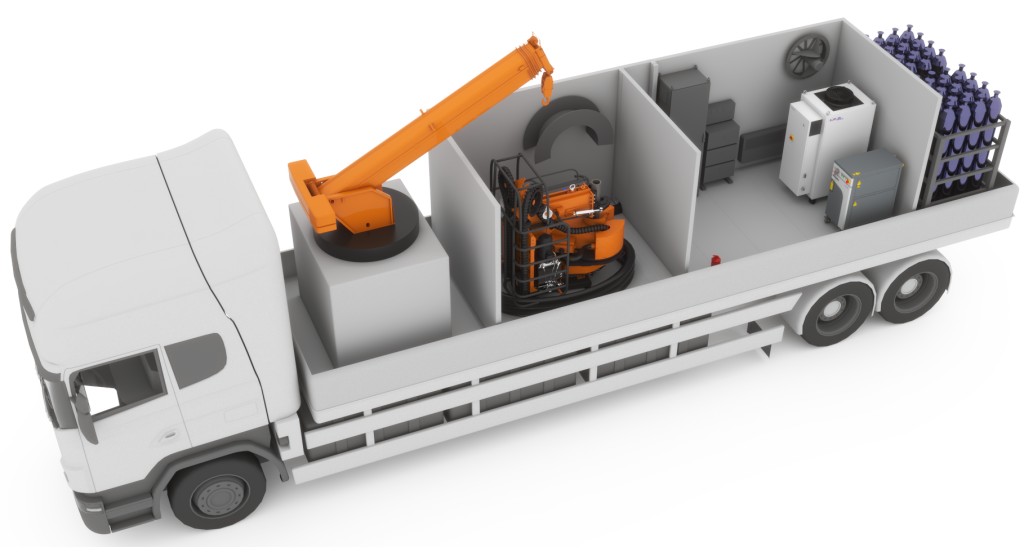

| Dimensions | 800x1500x1900 mm |

| Weight | 850 kg |

| Ambient temperature | -40 – +45° С at humidity up to 100% |

| Diameter | 4" – 7" or 7"– 9 5/8" |

| Thickness | up to 10 mm |

| Deviation from the end plane of welded pipe | <0.1 mm |

| Non-perpendicularity of the welded pipe end in relation to outer surface of pipe | <3 angular minute |

| Explosion protection | default |

| Built-in automated ultrasonic testing (AUT) of welding joints | optional |

| Pipe laser cutting | optional |

| TongWeld Equipment: | -Ytterbium fiber laser YLS-10000 -Chiller water-air LC-170 -Optical head for welding FLW D50 -N2 Bundle -Hydraulic station (for clamps and vertical positioner) -Pneumatic Cabinet -Electrical Cabinet -Remote Controls |

contact us

Want to Learn More?

Contact VPG LaserONE using this form, and learn what the TongWELD Automated Casing Laser Welder can do for you!

Contact TongWELD Sales

By continuing to use the site, you consent to the use of cookies in accordance with our Privacy Policy